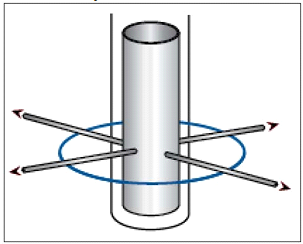

Radial Drilling Technology Radial drilling technology is a modified coil tubing system that uses high-pressure fluids combined with hydraulic impact forces to penetrate the reservoir rock. This is achieved by utilizing the jetting forces and covert it to forward and rearward forces at a certain flow regime and in a certain pattern. This will create enough forward energy to cause erosion to the formation. Forward movement becomes a function of the hydraulic forces available at the jet as thrust, to propel the jet forward. This is achieved from spherically arranged rearwards jets.

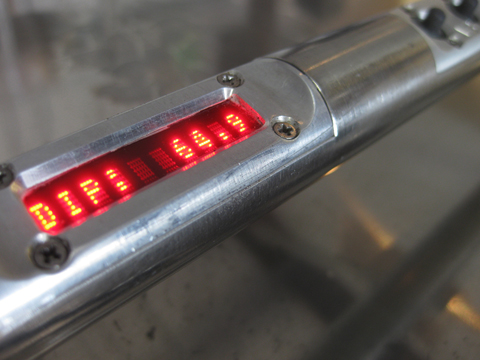

High-pressure fluid is generated in the surface unit and conducted to the jet thru a specially designed high pressure, small OD coil tubing arrangement, and a flexible high-pressure hose for the part of the system that actually enters the formation. The coil tubing remains in the vertical (or angled) part of the wellbore whereas the flexible hose is guided thru a preset radius deflector system allowing the change from vertical to horizontal. The system is designed with two sections, an upper or surface section that is mainly a high-pressure system, and a down-hole system that is the actual formation penetrating assembly. The surface system comprises: ⦁ Power generating section, which includes an engine, fluid tanks and control, functions. ⦁ High-pressure section with pumps that generate up to 15,000 psi of surface pressure complete with all piping and auxiliary pumps for acid and other chemicals that maybe injected into the fluid stream. ⦁ Reeling compartment houses the coil string, hydraulic connectors for the injector head, and other auxiliary hydraulic components. ⦁ Control cab houses the surface unit control devices for control of the overall system

Radial Drilling is an emerging enhanced oil recovery technology that uses high-pressure water to drill a radial pattern of lateral tunnels into a producing formation, from an existing vertical well.

Radial Drilling is an efficient EOR method to optimize production in oil and gas wells. Four 100 meter laterals can be jetted in any one horizon in vertical and highly deviated wells getting you increased access to your reservoir. Unlike Fracking, material is removed from the formation creating an open 2” OD channel up to 100 meters (300 feet) in length.

Radial Drilling is highly versatile technology with a range of applications from well enhancement, increased injection rates in disposal wells, deep acid penetration, directed frac applications and frac replacement solutions through it’s “Frac-Less” service. RDS is intensely committed to Research and Development to meet customer demands to fight production decline.

Radial drilling could increase production from existing wells by 500%-1000%, and considerably increase the ultimate recovery from wells and formations where RJD is successfully deployed.